In the Swedish city of Växjö, municipal property company Vöfab is taking ambitious steps toward more sustainable construction. As part of the Interreg Circular Trust Building (CTB) project, Vöfab is leading a pilot initiative to explores how building materials can be reused more effectively in future renovations and new developments.

The pilot focuses on the renovation of Building G19 at Linnaeus University, and the first milestone has already been reached: a detailed inventory of the building’s reusable materials has been completed.

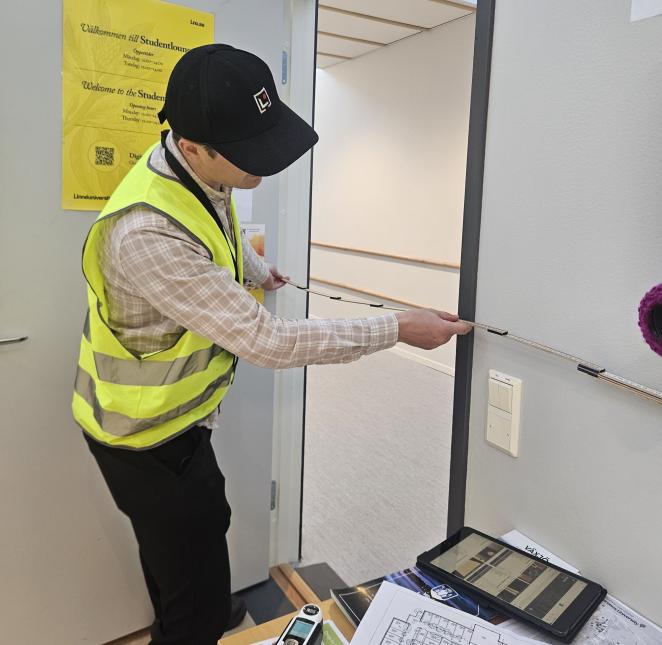

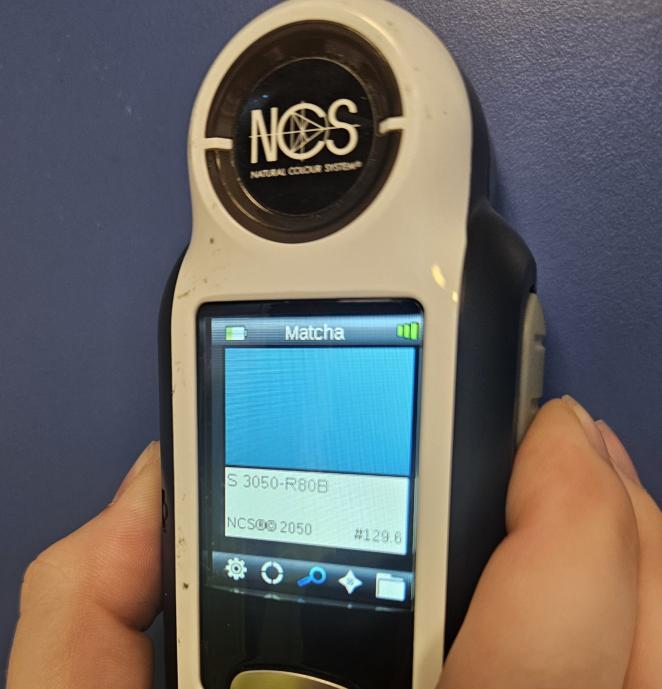

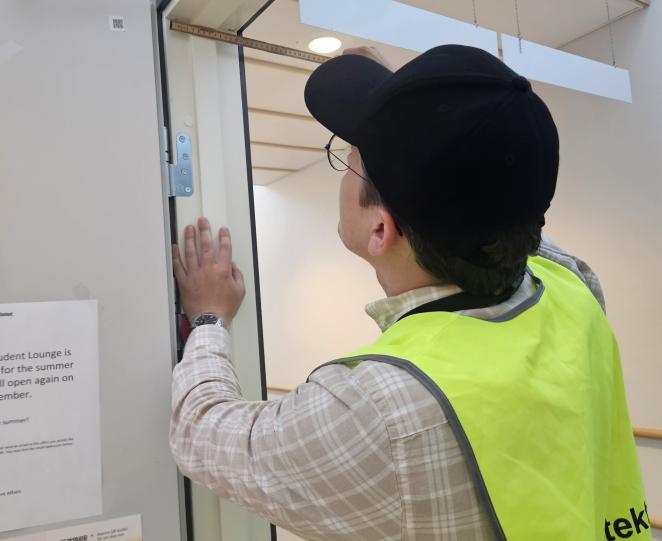

A methodical approach

Architect David Forssgren from LBE Arkitekt, who led the inventory process, explains:

“We reviewed all fixed furnishings and removable materials, visually assessed their condition, and documented everything in the CCBuild tool. We captured technical details—like door thickness—and noted any labels or approvals found on site. The goal was to make each material fully traceable and usable in the redesign.”

A key element of this process was creating a clear and structured “product box” for architects—essentially a ready-made portfolio of reusable components. This ensures reused materials can be integrated into new designs just as easily and reliably as new products.

The CCBuild platform

Vöfab selected CCBuild for its user-friendly structure and powerful data capabilities. One of its standout features is the ability to calculate climate savings for each item that is reused rather than purchased new. These savings are calculated using standard emission values for manufacturing and transport of new materials.

In the case of Building G19, the total climate savings potential is estimated at 25,000 kg CO₂e.

To put that into perspective: one round-trip flight between Stockholm and Málaga emits around 1,000 kg CO₂e—so this reuse effort could potentially save emissions equivalent to 25 such flights.

Currently, the inventory remains internal, as Vöfab plans to reuse most of the materials in-house. However, CCBuild’s flexible system means that materials can be made public later if needed—ensuring no resource goes to waste.

Reflections & recommendations

David Forssgren emphasizes that reuse inventories should evolve with the project timeline:

“Trying to complete a full inventory all at once is challenging and expensive. Instead, start with a broad overview early on, and return later to document more specific components. Some materials—especially built-in ones—can only be properly assessed after dismantling.”

This staged approach not only improves accuracy but also keeps the process cost-effective and adaptable.

As Vöfab works toward becoming one of Europe’s greenest property companies, this CTB pilot highlights how structured reuse strategies—and the ability to quantify climate benefits—can drive smarter, more sustainable decisions across the construction sector.

Photos: Godahus/Vöfab

Thanks to Erika Bernstone