ESBJERG AIRPORT SMART FENCING´S SURVEILLANCE (Pilot 6.1)

A fencing was installed to secure the areas designated for setting up a helipad for drones. Potential development of direct air connectivity between key offshore wind energy hubs (The North Sea Route) was investogated by LYGG. The fastest roadmap for sustainable flights (SAF vs. Electric or Hydrogen fueled aircraft) was identified, thus following Den Helder Airport´s path toward Advanced Aerial Mobility.

Tests with a (leased) inspection robot were carried out. It can detect holes in the fencing before they are visible to the naked eye. There are potentially several additional applications to it, making it multifunctional. By mounting some type of microphone, it could be employed to scare birds away. It might also be adopted to optimize the de-icer fluid applied on the runway, ensuring it is only utilised when necessary. This would provide both economic and environmental benefits.

VIVES GROUND ROBOT FOR AUTONOMOUS LOGISTICS HUBS PERIMETER´S SURVEILLANCE (Pilot 6.2)

As part of Work Package 2 – Sustainable Solutions in Logistics Hubs, DIOL is testing innovative technologies to enhance services for existing offshore wind farms and energy islands. This includes improving surveillance of energy infrastructure and perimeters in relevant ports and airports.Specifically, DIOL is preparing the groundwork for introducing, piloting, and validating the use of drones, ground robots, and AI-based technologies for security, monitoring, and maintenance of offshore renewable energy installations and connected logistics hubs. The VIVES Drone Applications Research Group, based at Drone Dock near Ostend-Bruges International Airport, was the logical choice for executing this pilot. VIVES brings extensive expertise in operating autonomous aerial and ground systems.

For the development of its prototype ground robot, VIVES collaborated closely with Zygo, a start-up specializing in tailor-made autonomous solutions for robots and drones, including software, hardware, cloud services, prototyping, and end-to-end testing.Traditionally, perimeter inspection at the airport is performed manually by personnel driving along the perimeter fence and visually checking its integrity. With today’s technological advancements, this task can be automated. To accelerate development, an existing platform was adapted for the prototype, with significant upgrades to both hardware and software. A key component was the fleet management software, enabling centralized control of multiple robots and over-the-air software updates.The project also included creating a simulation environment of the airport, allowing the robot to train virtually rather than physically on the runway—significantly speeding up navigation algorithm development.

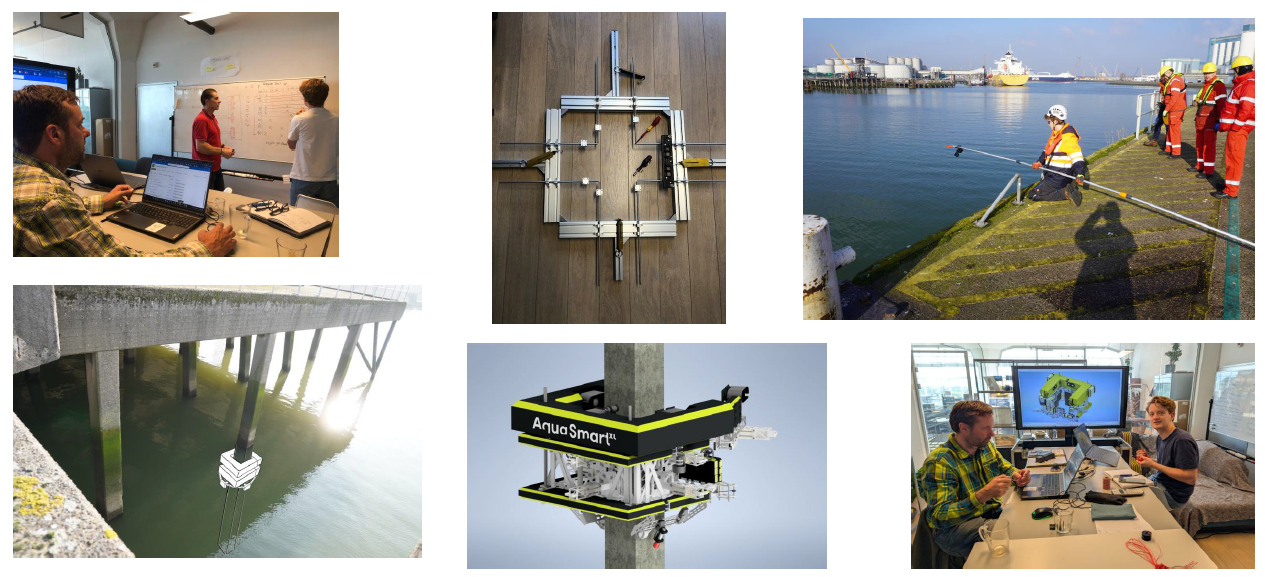

AQUASMART AUTONOMOUS/UNMANNED UNDERWATER, SURFACE AND CLIMBING VEHICLES (Pilot 6.3)

AquaSmart has been developing autonomous/unmanned underwater, surface and climbing vehicles in support of logistics hubs (focus on ports/airports) and energy projects. The work includes:

Climber Robot & ROV

USV

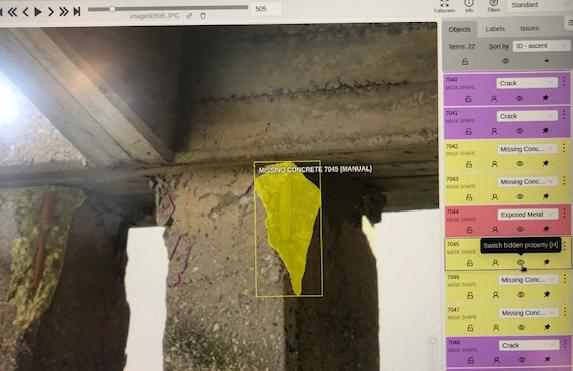

AI-based Damage Recognition activities to enhance data processing and provide civil engineers and material experts with higher-quality digital reports